Evaluate your Equipment

Assess for Success

How can you get to where you want to be if you don't know where you are?

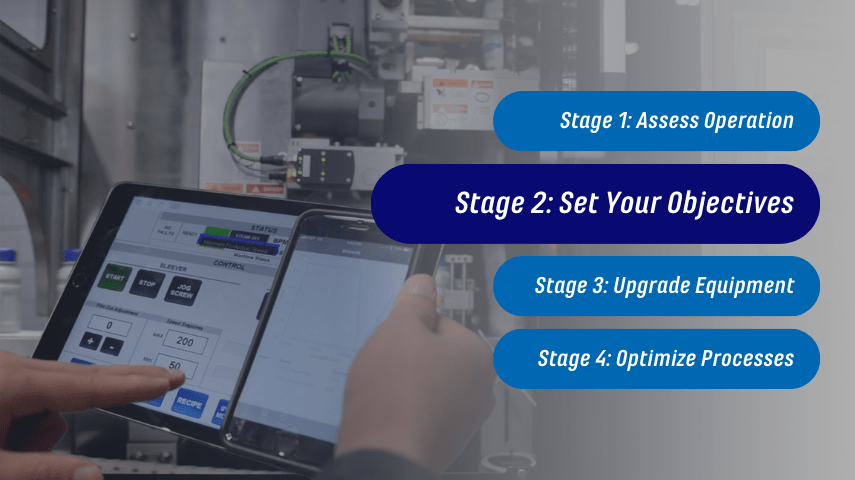

Figuring out where you are today helps you create your modernization roadmap for tomorrow.

The AIMM Services Modernization Assessment Program uses scalable plant assessments to provide ongoing insights into your facility's current condition, performance, and capabilities. Through regular Modernization Workshops, the program aligns assessment data with your objectives, creating a tailored modernization plan updated to reflect changes in your journey.