Is your industrial network prepared for a cyberattack?

A secure industrial network safe from cyberattacks is a journey, not a destination.

Industrial cybersecurity has always been a critical consideration for manufacturers. Recently, attacks have increased in frequency, sophistication, and destructive impact. In the past two years, cybersecurity attacks are rapidly increasing in frequency and impact. Manufacturing has been hit particularly hard, with hacks causing whole facilities to come to a screeching halt, disrupting supply chains and costing manufacturers millions of dollars as they scramble to repair breaches and restore their operations.

What does this mean for you? How do you better understand how prepared your facility and the steps to take to identify threats and secure your network, be it pre, during or after a cyber attack?

1. Understand the industrial cybersecurity landscape

If you Google search “cybersecurity”, more than 790 million results appear. With all the information about cybersecurity threats, hacks, news, etc. it is incredibly easy to be overwhelmed when trying to understand the cybersecurity landscape.

One thing to consider when searching for information is that cybersecurity needs for industrial OT (operational technology) networks is more complex than companies that only have an IT (information technology) network and requires special considerations. As a rule, IT manages data and OT manages machines. What may stop a data breach may or may not apply to a PLC being switched off causing part of the operations to cease.

As you strive to gather more data and improve efficiency and connect more and more devices to your networks, the reality is it can also leave your production vulnerable to cyber-attacks. An attack that often comes through an everyday activity on an IT network can then grant hackers access to your plant network, compromising your OT network and putting your most valuable assets at great risk. These assets are physical in the case of an Industrial OT environment. Understanding that risk and taking proactive measures now can save you millions of dollars in the future.

To make it easier to find industrial cybersecurity educational resources, we have compiled some of our favorites HERE.

2. Evaluate your current state

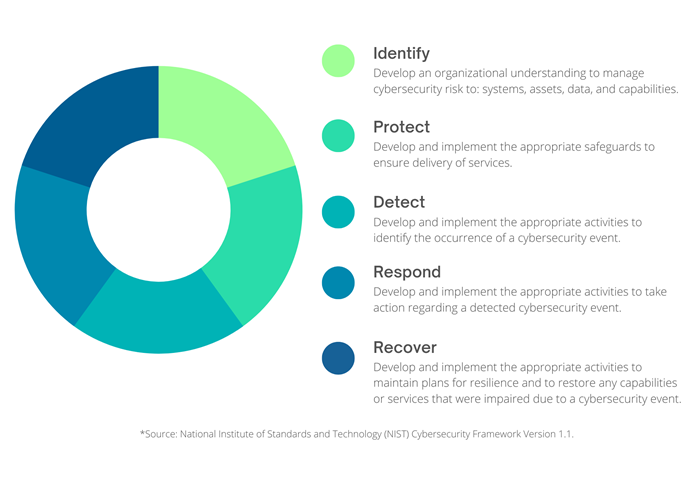

The National Institute of Standards and Technology (NIST) created a voluntary framework with standards, guidelines, and best practices to manage cybersecurity risk (see graphic below). As mentioned previously, a secure industrial network safe from cyberattacks is a journey, not a destination, and the framework is reflective of that.

Once you have identified your cybersecurity risk, you will be able make informed decisions to set standards and practices to effectively manage threats.

To help you evaluate your current state, we offer a free cybersecurity preparedness assessment and consultation to help you understand how secure your facility is.

a. Cybersecurity preparedness Survey

b. Consultation – Unlike most consultations, our free cybersecurity consultation will not be focused on selling you anything – we promise! The consultation with our experienced, qualified specialists is focused on learning more about your operation and where you might need assistance. After the consultation we will work diligently to create and deliver a plan specifically created to address your needs.

3. With your current state defined, it’s time to make a plan

Wherever you are in your journey, we have cybersecurity solution consultants and specialists to help you build, deliver, and support a plan specific to the needs of your industrial facility. CLICK HERE to get started on your cybersecurity preparedness journey today!